Key Features

Applications

Automotive and Component Manufacturing Lines

Paint Shops and Conveyor Controls

Process and Utility Automation Systems

Water Treatment Plants and Pump Stations

Packaging and Material Handling Equipment

Special Purpose Machines (SPMs)

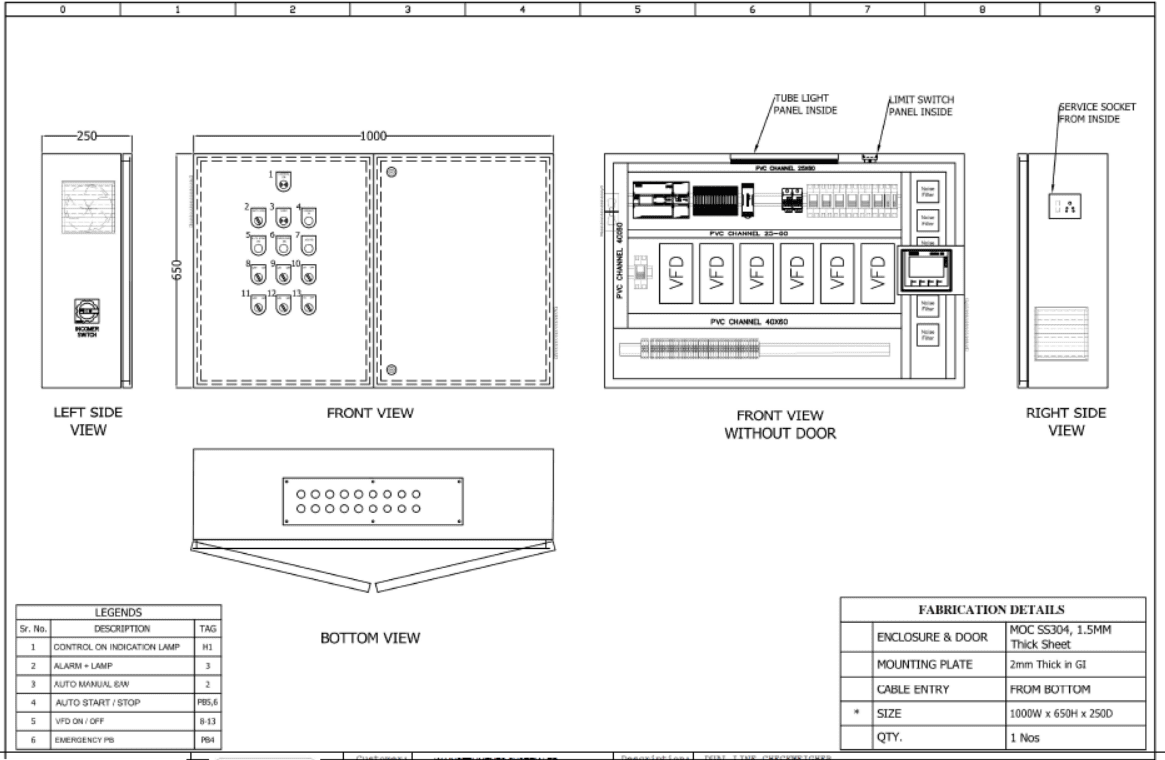

Documentation & Standards

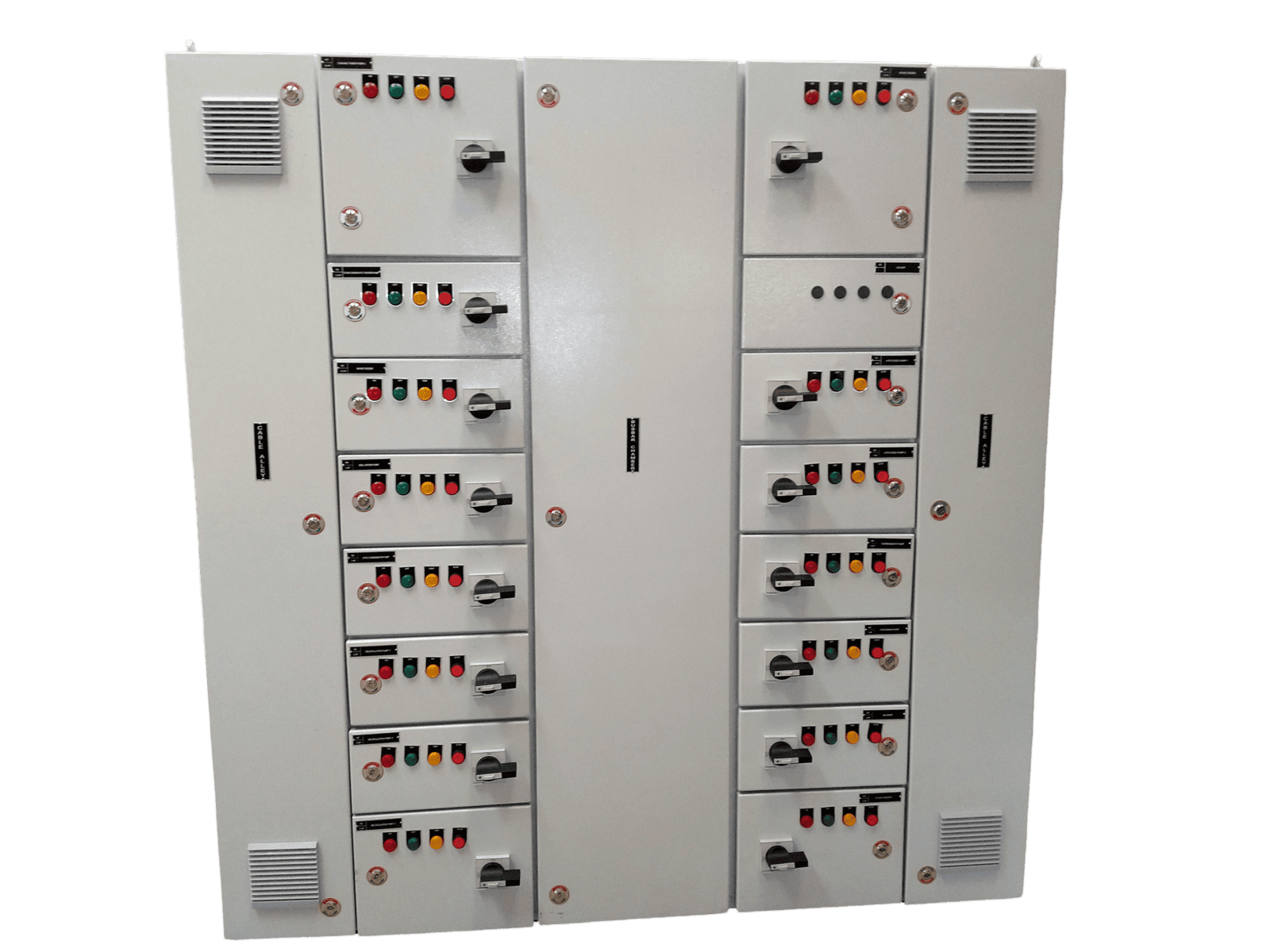

Each panel is supplied with:

Electrical Schematics (Designed using WSCAD)

Cable Schedule and Terminal Details

Panel GA and Wiring Diagrams

Functional Logic Descriptions

FAT / SAT Reports and Test Certificates

Why Choose Us

Over 10 Years of Experience in Automation and Control Panel Design

Proven track record with leading industries.

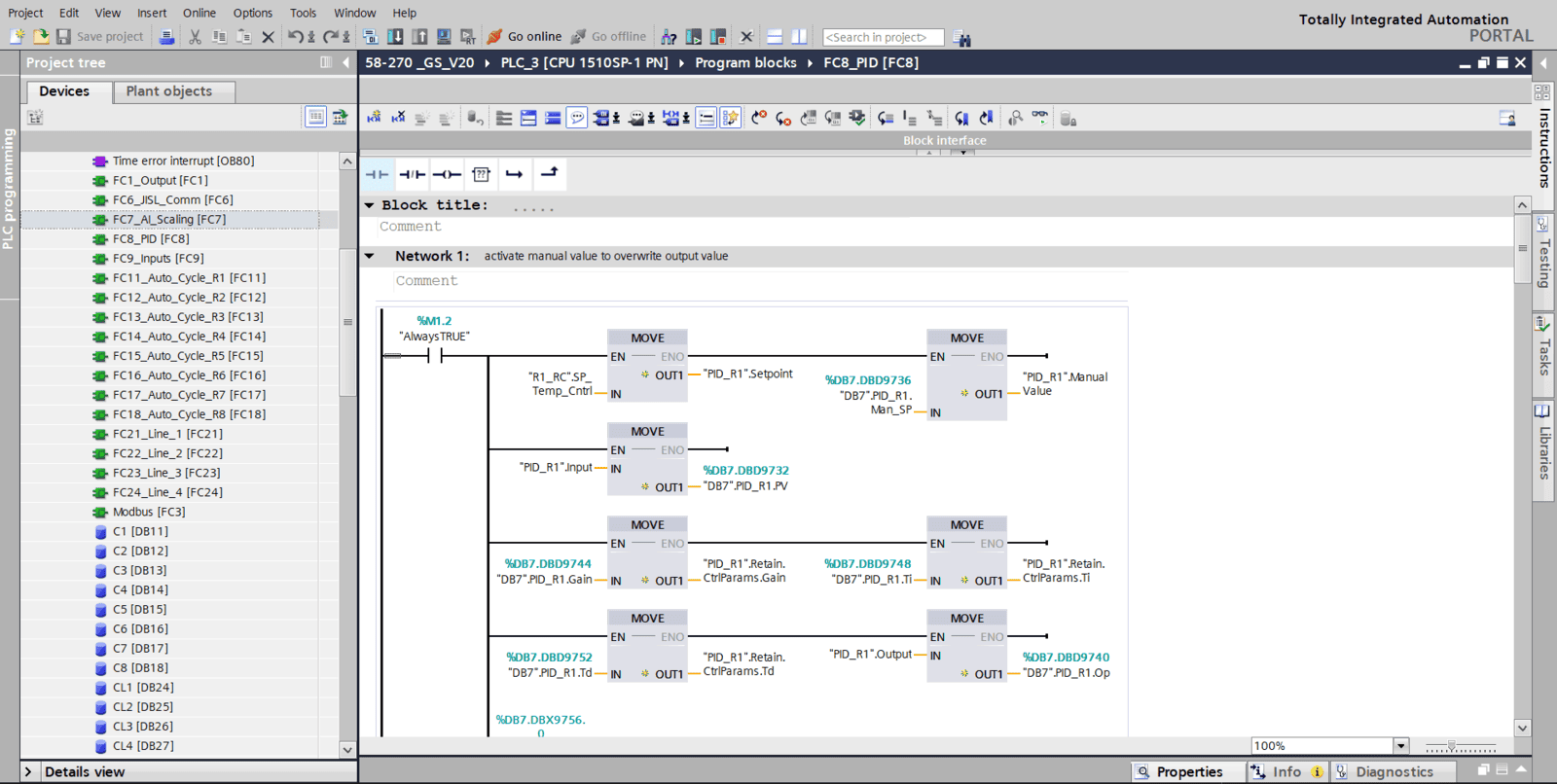

Dedicated team trained in Siemens TIA Portal, Step 7, and WinCC environments.

Onsite installation, commissioning, and service support across India

Customized solutions designed for scalability and future expansion

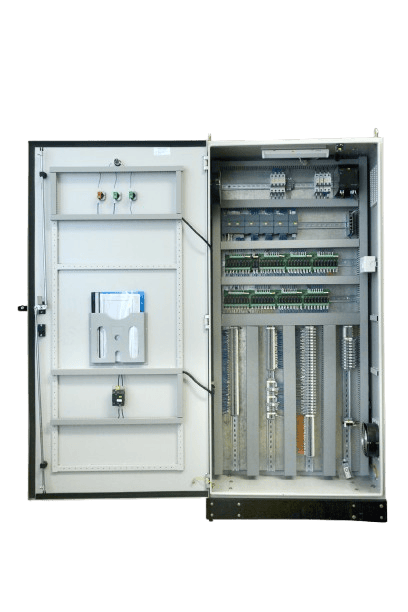

Key Features

Design & Engineering Capabilities

Detailed electrical design using WSCAD and AutoCAD

Load calculation, busbar sizing, and thermal management design

Component selection and panel layout optimization

Interfacing with PLC / SCADA systems for intelligent control

Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) documentation

Key Features

Applications

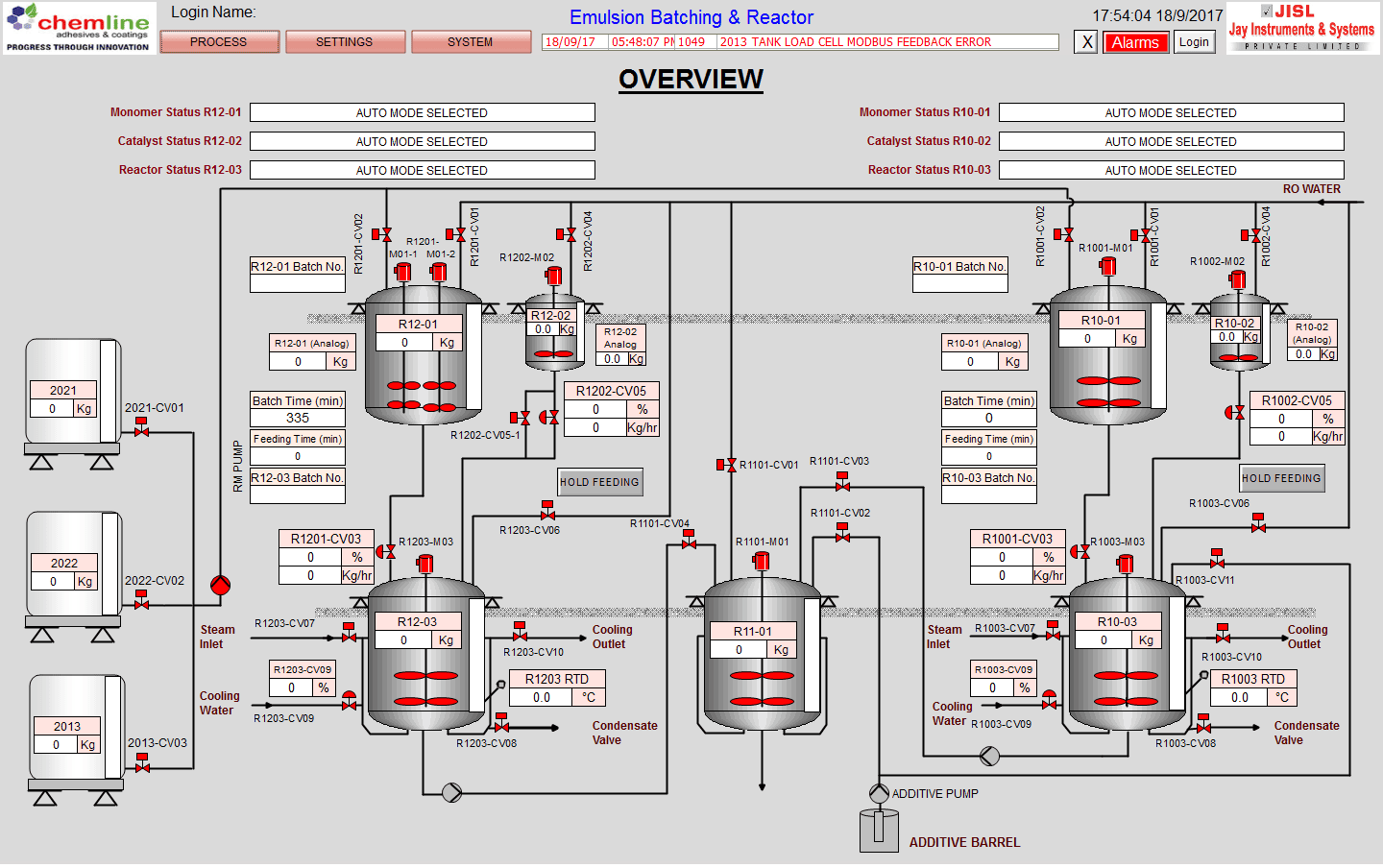

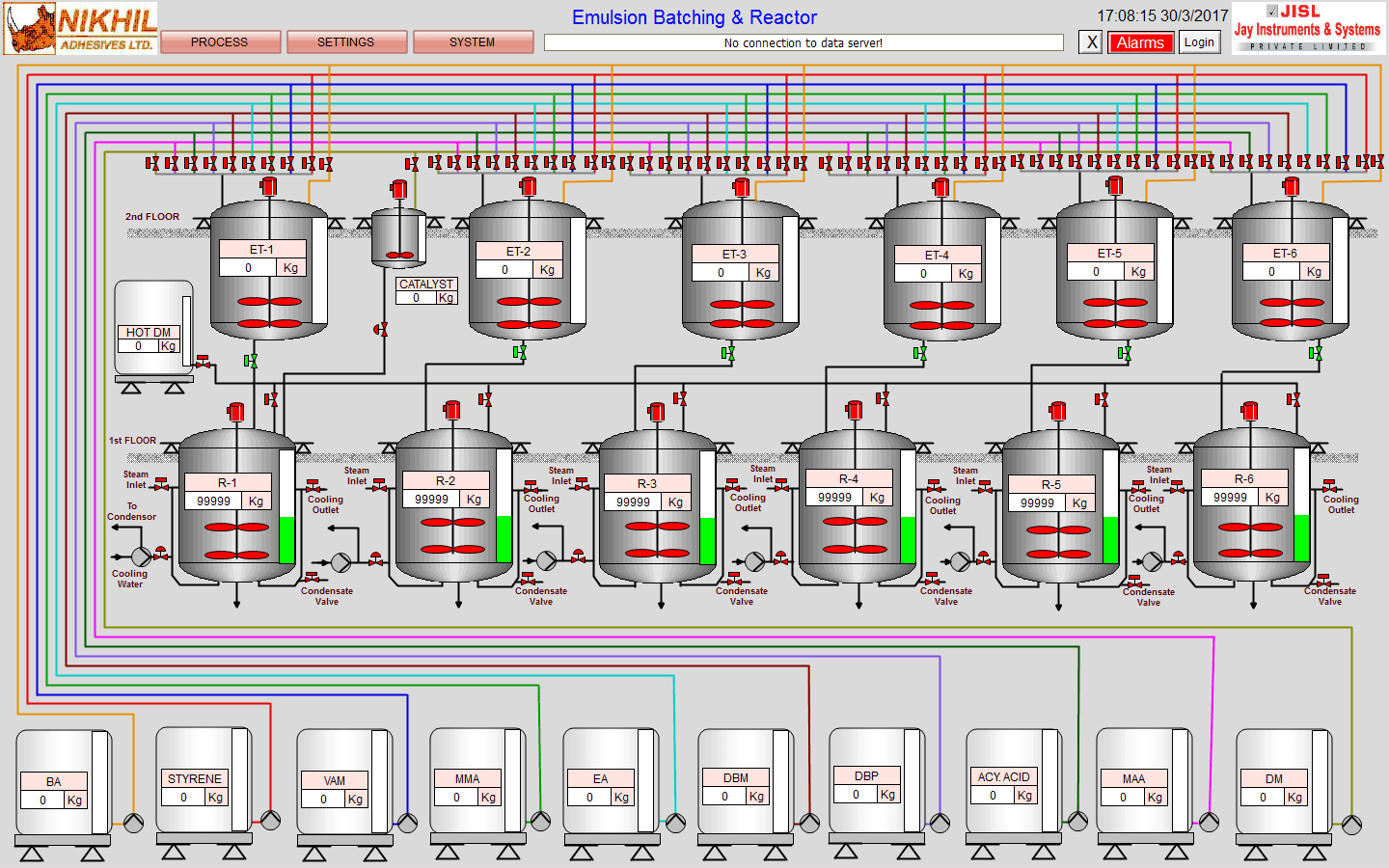

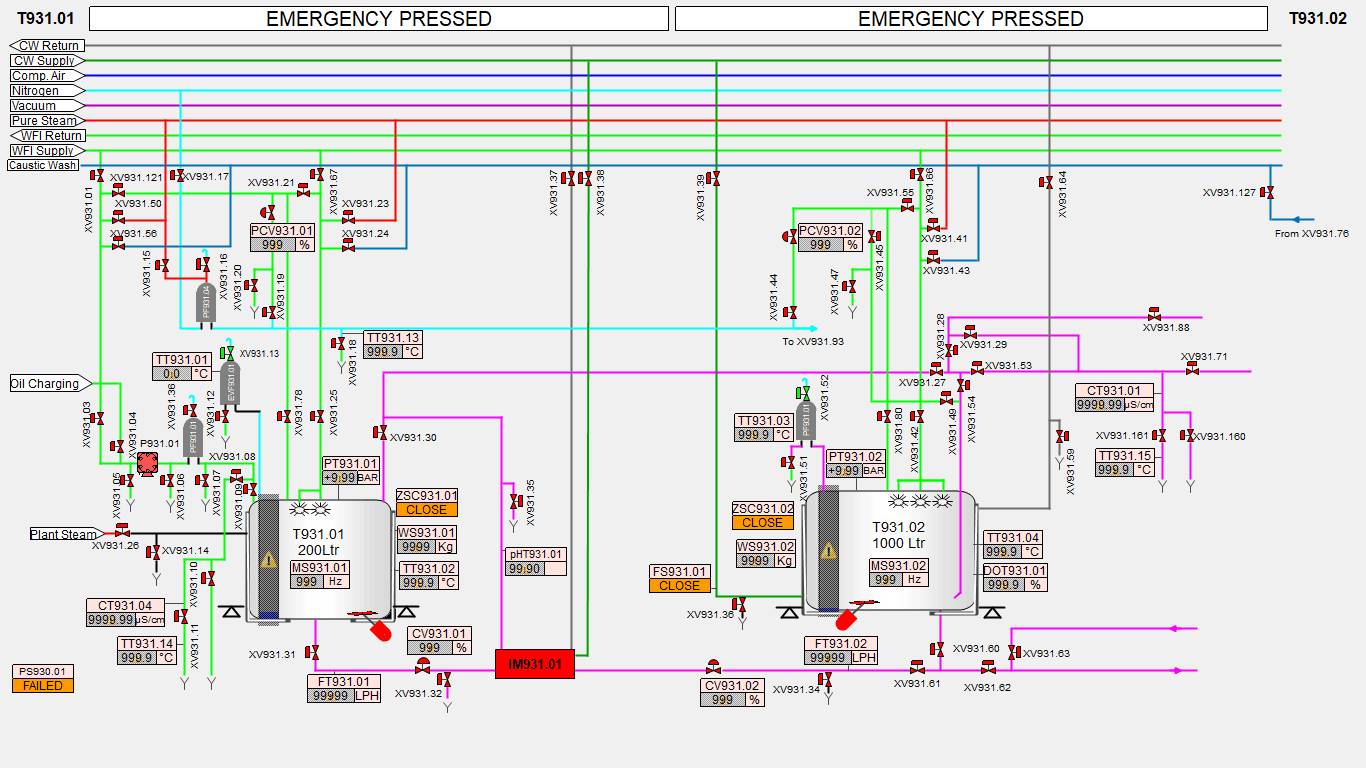

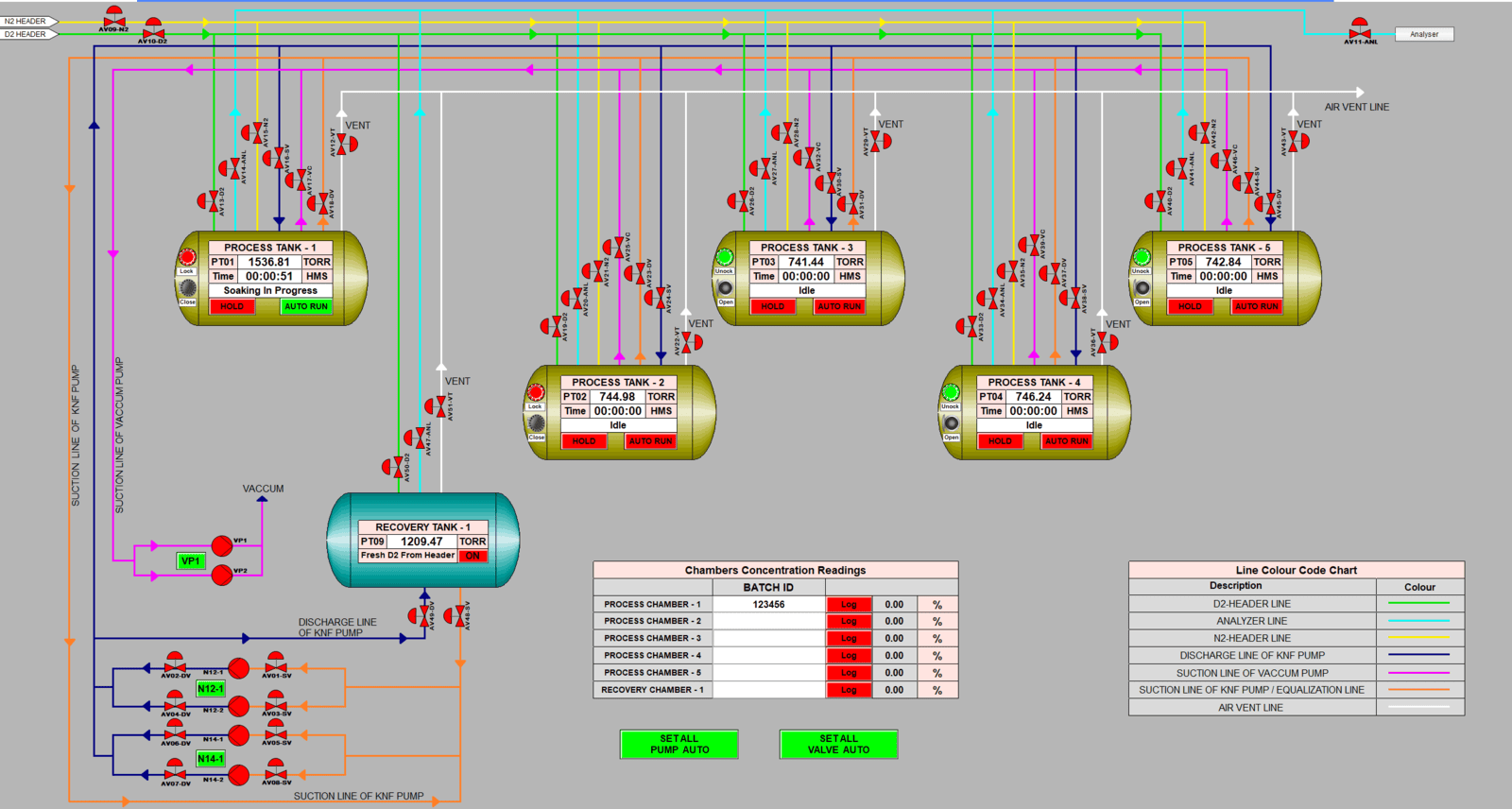

Process Plants (Chemical, Food, Pharma, Water Treatment)

Utilities and Energy Management Systems

Batch Process Automation

Automotive Assembly and Paint Shops

Why Choose Us

Expertise in Siemens WinCC, TIA Portal etc.

Experience in designing 21 CFR Part 11 compliant systems for regulated industries

Comprehensive reporting and data logging solutions with automated PDF generation

Custom built graphics and process animations as per international visualization standards

End-to-end services including design, development, commissioning, and remote support

Our Services

Industries Served

Automotive and Component Manufacturing

Utility and Power Management Systems

Process Plants (Chemical, Pharma, Food, Water Treatment)

Special Purpose Machines (SPMs)

Machine Builders and OEMs

Paint Shops and Conveyor Automation

Key Features

Why Choose Us

Highly skilled team with strong domain knowledge in industrial automation

Proven track record with Siemens platforms and industrial communication systems

Over a decade of experience in PLC, HMI, and SCADA programming and commissioning

Focus on reliability, documentation, and after-sales technical support

Customized solutions designed for scalability and future expansion

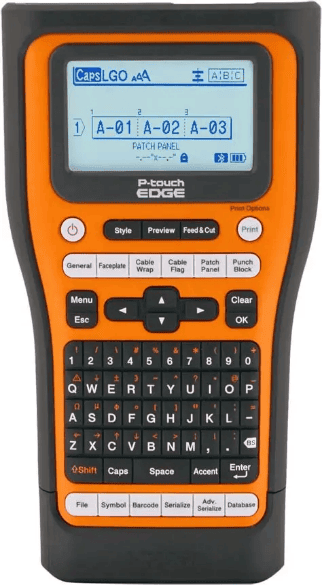

Brother Label Printers

Contact us to discuss your automation software development or commissioning needs.